WHERE WATER COLLIDES STEEL

DESIGN

Our design team with experience over 20 years can provide draft or detailed designs and offer sophisticated, reliable and cost effective technical solutions and accurate budget estimations even in the early design stages of project development.

Design and calculations can be performed and adopted according to international standarts and codes compliant with

- DIN 19704(2014-11), hydraulic steel structures

- DIN EN 1990, Eurocode: basis of structural design

- DIN EN 1991, Eurocode 1

- DIN EN 1993, Eurocode 3

- C.E.C.T

- ASME

- AWWA

Starting with 3D modelling we are able to perform computer based structural analysis, hydraulic flow analysis and fatique analysis of equipment.

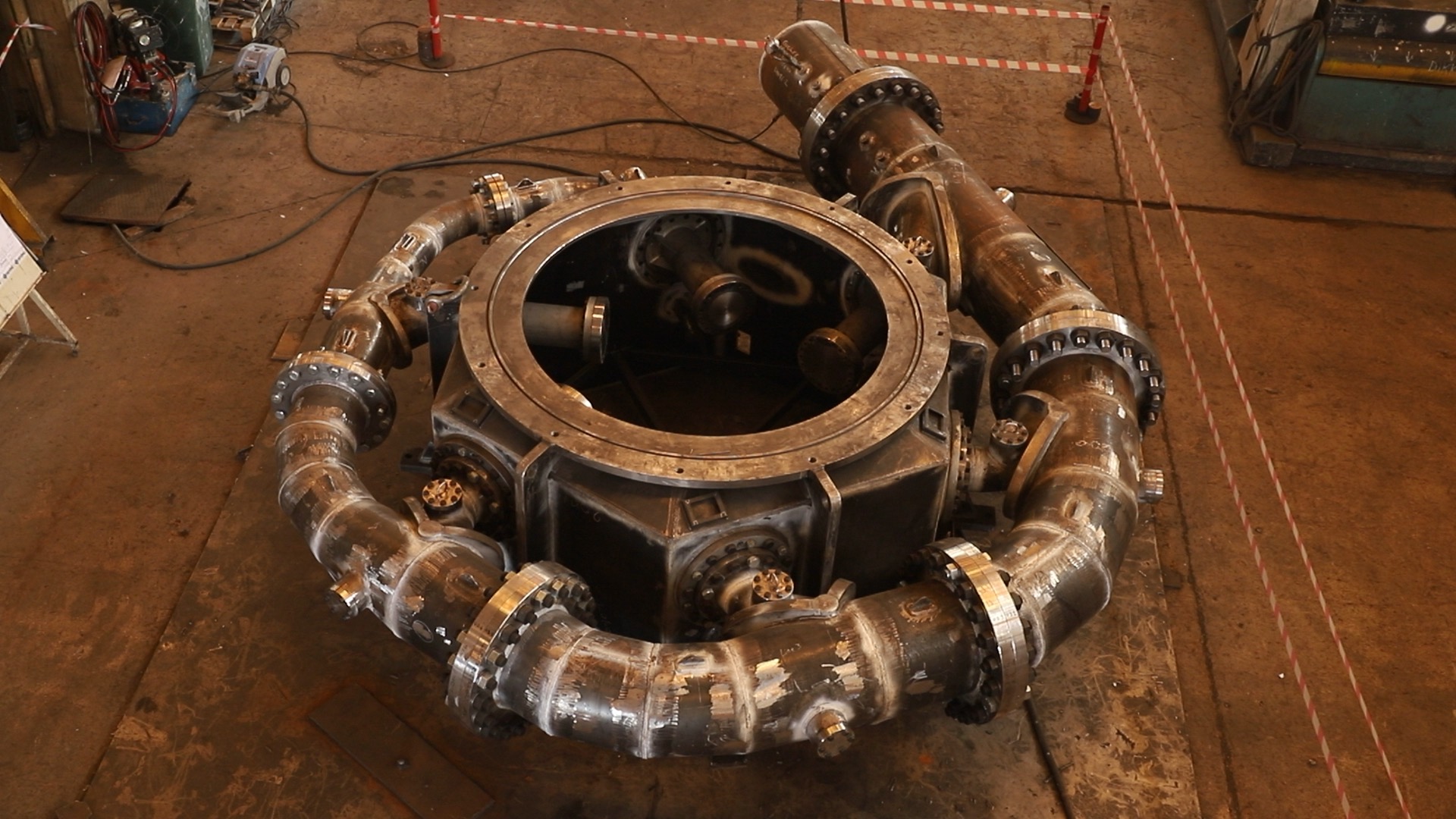

PRODUCTION

Our manufacturing facilities cover total 8.500 m² closed area built on 16.200 m² industrial land. In our factory we have inhouse manufacturing capacity of a single part up to 40 tonnes and our annual inhouse production capacity reaches up to 2.500 tonnes.

Location

Our headquarters and factory is located at Başkent Industrial Zone in Ankara only 40 km from city center. Our location presents remarkable advantages for international travel, logistic and transport activities having 1,5 km distance from railway station, 4,5 km to nearest highway access, 50 km to international airport and 380 km to nearest sea port.

Personnel

Working together through decade long periods, passing experiences and industrial culture through generations we believe our employees are our companies most solid and valuable asset.

As SEVİNÇ team we are all alligned together to produce high quality and customer oriented services.

Our employees has always been enthusiastic for what they do and always be ready to take any chalenging tasks to meet customers contemporary requirements.

INSTALLATION

Being involved in more than 200 projects and having been comissioned more than 80.000 tonnes of equipment. We have exercised working on many different terrains and climates cooperating with many different employers.

We are always concious that we are a key partner during and after project implemantation and construction works and appreciated by stakeholders as a reliable and trustworthy company thanks to our dedicated project management team and professionel employees performing all tasks timely acording to project schedules.

According to project requirements we are also able to offer flexible mobilisation options for manufacturing processes at site.

MAINTENANCE-REPAIR

In the operation of hydroelectric power plants our company aims at a quick completion of the work and a commissioning of the plant in the shortest time possible when it comes to malfunctions, maintenance and repairs that will break the continuity within the system.

We continue to provide the right solutions for failures, maintenance and repair services without compromising on quality.

REHABILITATION

Many rehabilitation activities in hydroelectric power plants are successfully realized with SEVİNÇ MAKİNA's expert staff and high institutional experience.

Sevinç Makina A.Ş. has completed many projects in terms of design, manufacture and installation of hydro-mechanical and permanent equipment in the scope of construction of dams and hydroelectric power plants, regulator structures and irrigation systems in every region of Turkey.

PROJECTS